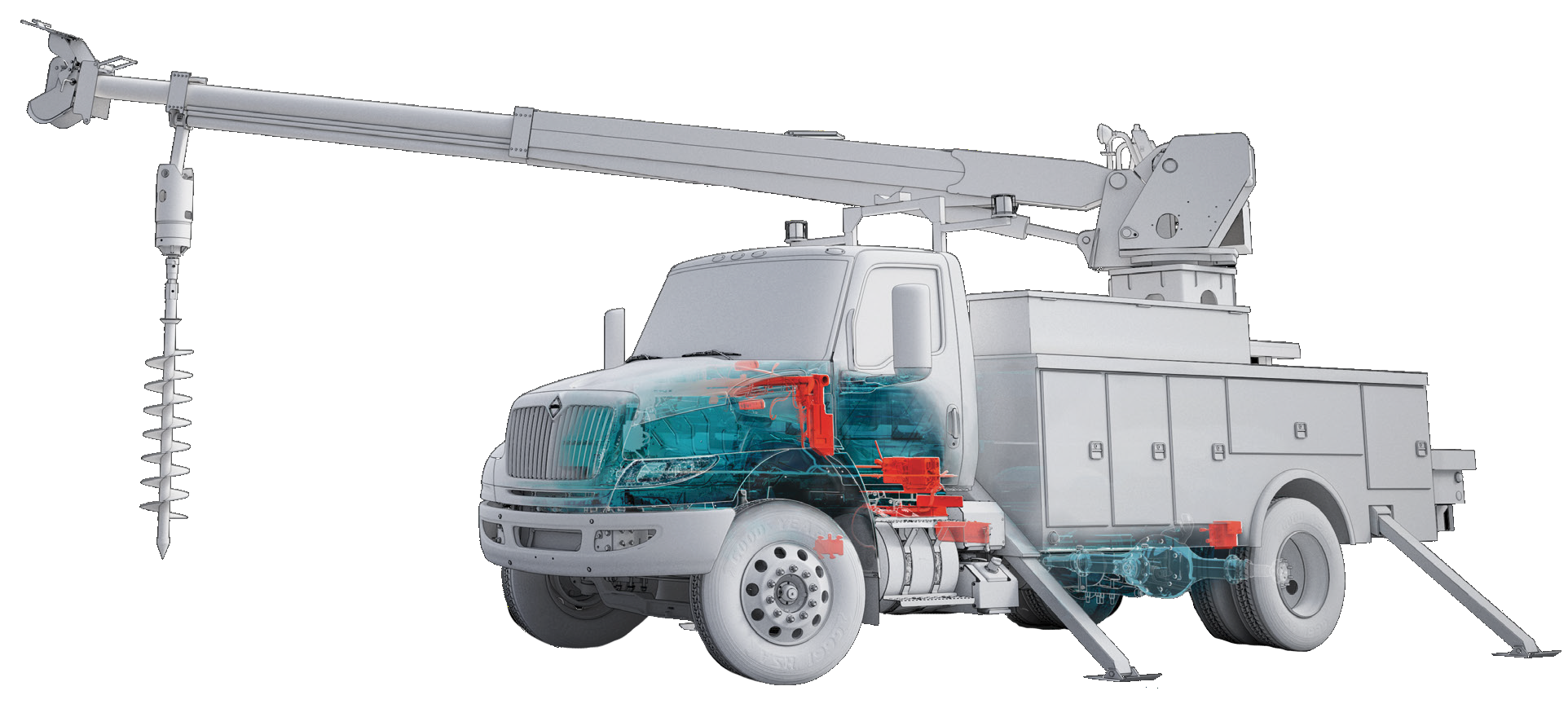

WHEREVER YOU LOOK, DIAMOND LOGIC® IS PROGRAMMED TO SUCCEED.

Whether you’ve got a single truck or a whole fleet, Diamond Logic brings the brainpower, flexibility and convenience to suit almost any application. With nearly 200 available factory body integration and driver efficiency features, plus the ability to custom-program virtually any type of need, Diamond Logic brings a new level of safety and precision to the jobsite.

Body Controller

- Heart of the Diamond Logic System. Performs all body integration software execution to maximize safety, performance and ease of equipment installation

Switch Packs

- All switches are controlled via 6 wires

- Blinking switch indicators provide equipment status

- Switches can be moved without moving wiring

- Up to seven colors of lights can be used

PTO (Power Take Off)

- Engagement and disengagement based on chassis and body conditions (engine speed, road speed, outrigger deployed before boom can raise, park brake set, transmission in neutral, etc.)

- Certain data links can be used as an interlock including RPM, MPH, Park Brake and gear position

- Engine speed can be controlled (in most cases) while using the PTO with no additional wiring needed

Remote Power Modules

- All 12-volt outputs are automatically fused (auto-resettable) with solid state technology

Outriggers

- Diamond Logic can sense when they are not properly stowed and will illuminate an indicator light in the switch packs while sounding an audible alarm

Differential Lock

- Diamond Logic can control when the axle differential locks and unlocks depending on road speed, protecting the driveline from damage due to excessive speeds in a locked position

Work Light

- Diamond Logic can automatically turn on or off the light based on chassis functions (for example: rear-facing light could be programed to turn on any time the transmission is in reverse, adding additional lighting)

- Automatically shut off the light based on a set forward speed

Boom Hydraulics

- Diamond Logic can sense when they are not properly stowed and will illuminate an indicator light in the switch packs with an audible alarm

Pre-Trip Light Inspections

- Driver can press a button and all the exterior lights will blink in sequence, allowing daily DOT light inspection with just one person

Solenoid Air Packs

- Air can be turned on with a switch in the dash or controlled based on chassis and/or body functions (for example: tailgate air lock in dump applications can be programmed to not unlock unless the truck is driving below a certain speed)

WAYS TO USE DIAMOND LOGIC®

- Order from nearly 200 preprogrammed tasks

- Work with International® to create custom tasks

- International can train and certify your technicians on Diamond Logic Builder software to independently program new tasks

DIAMOND LOGIC BUILDER

International customers have the ability to write custom logic so Diamond Logic can be easily expanded, configured and updated in the field to meet specific application requirements.

SAFETY AND PRECISION FOR ANY APPLICATION.

THE RIGHT SYSTEM FOR ANY TASK.

Whether you’re looking for an efficient, cost-effective solution for your municipality, a Truck Equipment Manufacturer (TEM) looking for a rock-solid foundation to build on, or a construction company wanting the toughest in the business, the Diamond Logic® System will get the job done with safety and precision others simply can’t match.

DRY VAN

- Door open warning light/alarm: can prevent loss of property while driving down the road or theft while vehicle is sitting; this can also prevent temperature loss and cargo spoilage in a refrigerated body

- Drive-time hour meter: Records time the vehicle has been driving and in use

- Cab and body door locks can be tied together so when the cab door is locked, the body doors are also locked

DUMP

- Clogged hydraulic fluid filter indicator

- Low hydraulic oil level indicator

- Tarp control: Automatically wind and unwind tarp; prevent product loss

FIRE/EMERGENCY

- Load management: Prevents discharging of the batteries, turns off lamp loads as battery voltage drops

- Redirect siren/horn switch: Depending on the situation, either the city horn or siren can be chosen

- Split-shaft water pump control: Automates steps to safely engage water pump system

PLOW

- PTO shutdown override momentary switch: Allows operator to override PTO shutdown in order to raise blade

- Tarp control: Automatically wind and unwind tarp; prevent product loss

UTILITY

- Cabinet lights & body lights can be set to timers to save battery power if the key is off. The set time can be programed by the customer

- Low voltage alarm warning: Indicates the battery voltage is dropping and that the operator should start the truck to address it

- Wheel chock sensors: These sensors check if the wheel chocks are stowed; reminds drivers to use and re-stow wheel chocks on the job site

REFUSE

- Customized automatic packing operation with safety interlocks. The number of times the waste is packed can be changed—1, 2, 3 times, depending on needs of customer

- Master body switch power with interlocks: Use of body equipment, PTO, packer, or engine speed are tied into specific safety conditions that must be met

- Rear lighting for back-up camera: To increase visibility for camera when it is dark, additional lighting can be added

Factory-installed switches with custom labels are used to control integrated equipment. When a reading is out of the programmed operating range Diamond Logic will alert the driver with an audible alarm and a visible LED indication on the switch pack, reducing the potential for costly equipment damage and maximizing uptime

WARNING

WARNING